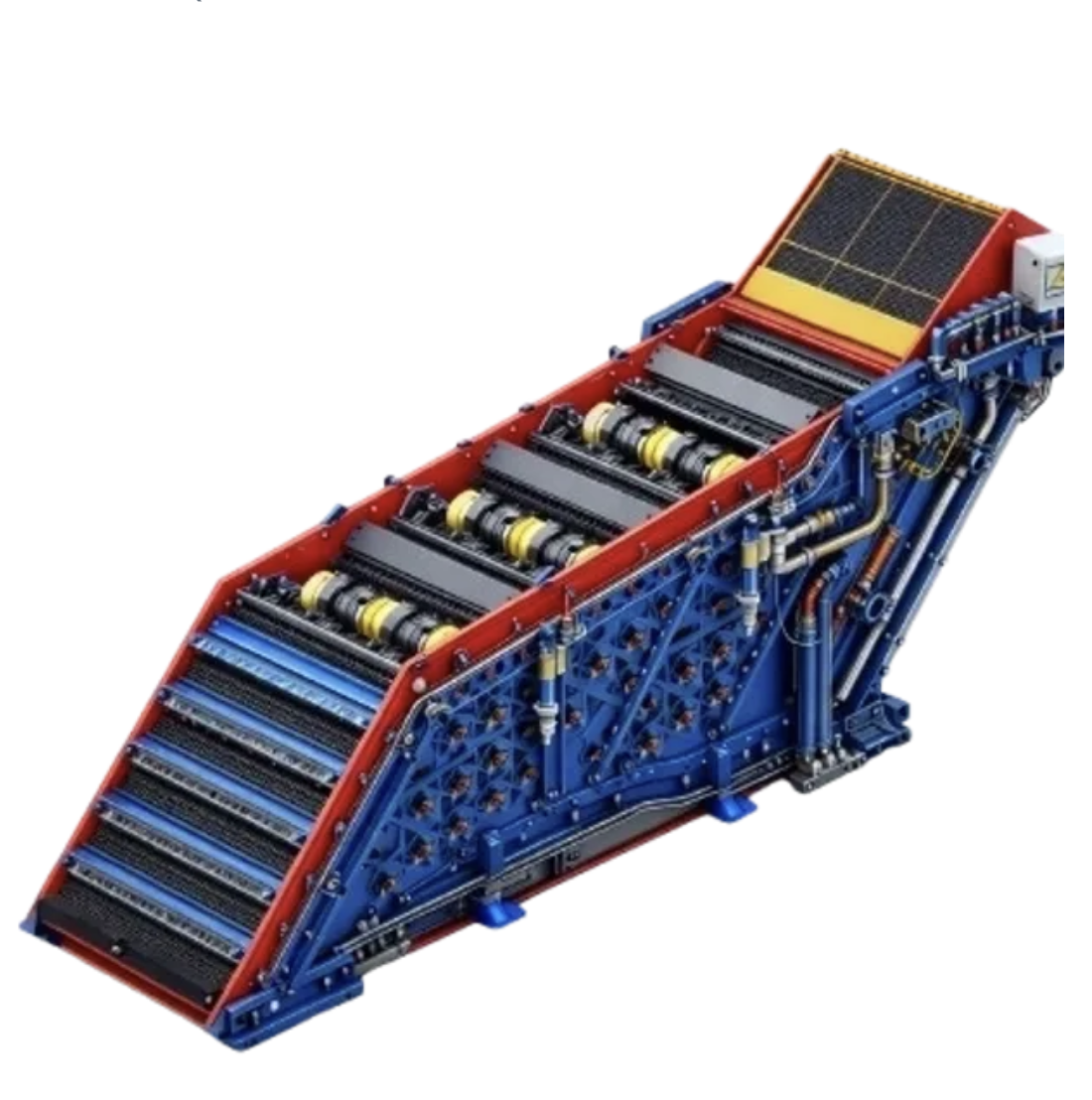

Advanced Screening Technology

CRUXTOR High Frequency Screens represent the pinnacle of screening technology, engineered specifically for modern industrial applications. Our purpose-built solutions deliver precise particle size distribution control, ensuring optimal performance across diverse industries.

- Operating speeds from 2,800 to 6,000 RPM for precise separation

- Stainless steel screening media for high-purity applications

- Energy-efficient operation with ultra-low power consumption

- Non-blinding performance even with fine materials

- Compact design with high throughput capacity

Key Applications

Manufactured sand with precise gradation control

Accurate particle size classification for sugar processing

Efficient screening for metallic and non-metallic minerals

Reliable grading for various fertilizer formulations

WELCOME

High Frequency Screen - fine screening technology used widely in M Sand Plant and Sugar Grader

The high frequency screen is an essential component of advanced screening solutions, designed for the fine screening technology of solid bulk material. It plays a crucial role in M Sand Plant operations and also serves effectively as a sugar grader.

SAND

High Frequency Screen for Sand Processing

Our high frequency screens are specifically designed for sand processing applications, providing efficient and precise screening for M Sand plants. The advanced screening technology ensures optimal particle separation and high throughput rates.

SUGAR GRADING

High Frequency Screen for Sugar Grading

Our specialized sugar grading screens deliver precise particle separation for sugar processing. The high frequency screening technology ensures consistent grading and quality control in sugar production facilities.

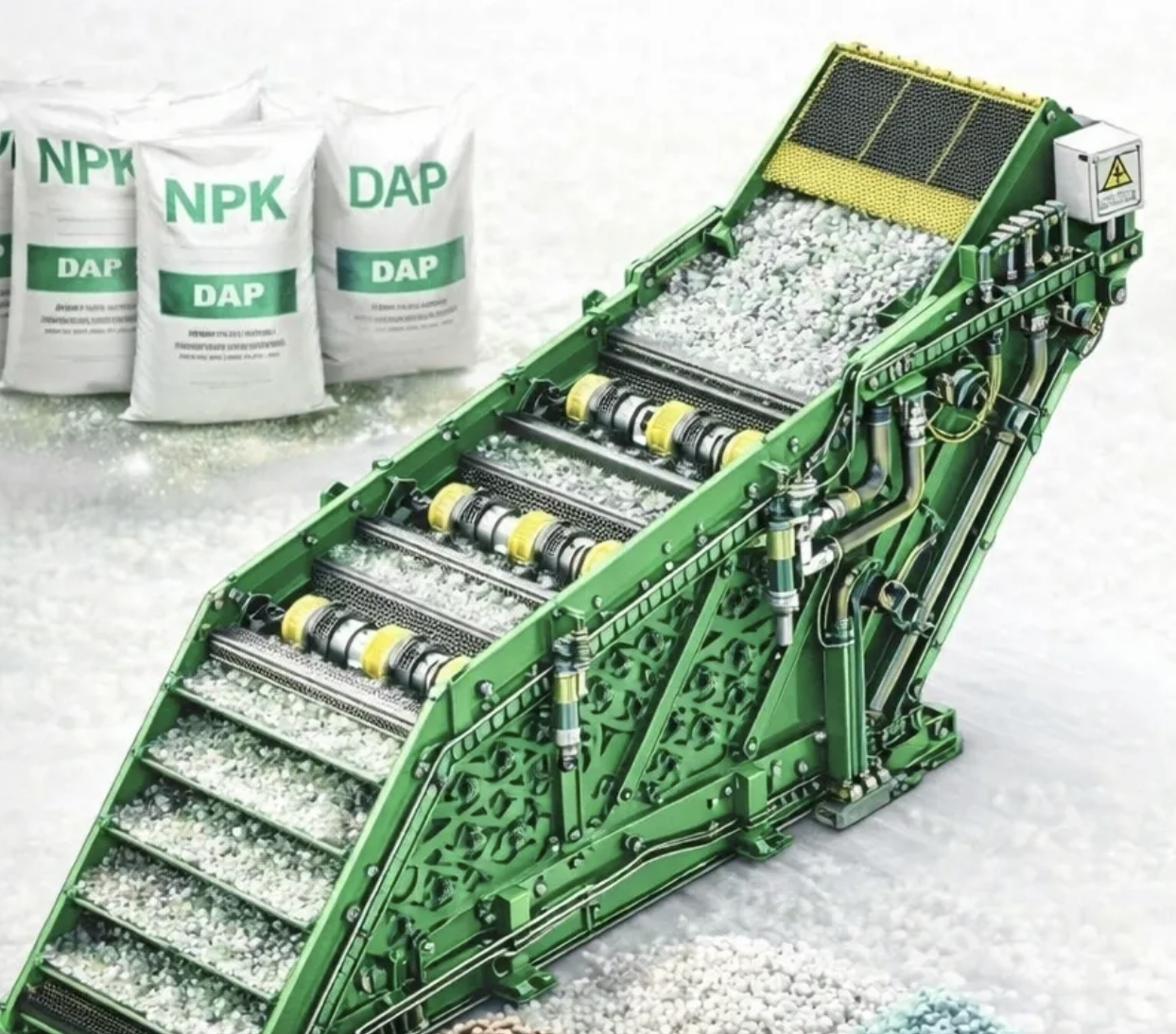

FERTILISER

High Frequency Screen for Fertiliser Processing

Our high frequency screens are engineered for fertiliser processing applications, providing efficient screening and grading of fertiliser particles. The technology ensures uniform particle size distribution and optimal product quality.

Quartz Powder Processing with High Frequency Screens

QUARTZ

High Frequency Screens for Quartz Processing & Quartz Powder Production

High Frequency Screens are advanced quartz processing equipment designed for precise particle size classification in quartz sand and quartz powder production plants. Operating at speeds ranging from 2,800 to 6,000 RPM, these screens are engineered to handle the hard, abrasive, and brittle characteristics of quartz while ensuring consistent quality and high throughput.

The system utilizes stainless steel (SS) screening media, making it particularly suitable for applications that demand high purity, dimensional accuracy, and long service life.

Why High Frequency Screens Are Ideal for Quartz Processing

Quartz processing requires sharp separation, minimal contamination, and reliable performance at fine sizes. High Frequency Screens effectively meet these needs through high-speed vibration and rigid SS screen decks.

Precise Fine Screening of Quartz Sand

High vibration speeds enable:

- Accurate separation below 1 mm

- Narrow and repeatable particle size distribution (PSD)

- Clean segregation of quartz sand grades

This makes High Frequency Screens perfect for quartz sand classification, beneficiation plants, and controlled feed preparation for grinding.

Stainless Steel Screening Media – Built for Quartz Production

The use of SS wire mesh and SS screen panels provides:

- High resistance to abrasion from quartz

- Dimensional stability at high vibration frequencies

- Suitability for high-purity quartz applications

SS media ensures consistent aperture accuracy, which is essential for both quartz sand and quartz powder production.

Non-Blinding Performance with Quartz Fines

At operating speeds of 2,800–6,000 RPM, the high G-force vibration prevents particle lodging in SS apertures, maintains an open screening area, and enables continuous operation without choking. This guarantees stable performance even with fine quartz material.

Reduced Over-Grinding and Energy Savings

Accurate screening ensures that only true oversize material returns to the mill, resulting in lower grinding energy consumption, reduced generation of ultra-fine quartz, and improved recovery of saleable size fractions. This directly lowers operating costs per ton in quartz powder manufacturing plants.

High Throughput with Compact Footprint

High Frequency Screens operate with a thin material bed, allowing faster particle travel and higher capacity per unit screen area. This makes them ideal for space-constrained quartz processing plants, retrofits, and capacity upgrades.

Role of High Frequency Screens in Quartz Powder Production

In quartz powder production, product performance heavily relies on particle size control and consistency. High Frequency Screens are integral for pre-classification before grinding, post-grinding size control, and tight PSD management for downstream applications. This enhances powder uniformity, reduces mill load, and boosts overall plant efficiency.

Applications of Quartz Powder

Quartz powder screened using High Frequency Screens is extensively used in:

- Glass and specialty glass manufacturing

- Ceramics and vitrified tiles

- Paints, coatings, and wall putty

- Electronics and semiconductor fillers

- Construction chemicals and epoxy flooring systems

Key Advantages at a Glance

- Operating speed: 2,800–6,000 RPM

- Stainless steel screening media for accuracy and durability

- Sharp cut sizes for quartz sand and powder

- Non-blinding performance with fine quartz

- Lower grinding energy and operating cost

- Compact design with high throughput

Reliable Screening Technology for Quartz Processing

High Frequency Screens with SS screening media are a proven solution for quartz mining, beneficiation, sand processing, and quartz powder production. They deliver consistent product quality, reduced operating costs, and long-term reliability in demanding quartz applications.

About High Frequency Screen

Silica Sand

High Frequency Screens for Silica Sand Processing & Classification

Silica sand processing requires high precision screening, consistent particle size distribution, and minimal contamination. High Frequency Screens are widely used in silica sand beneficiation and processing plants to achieve accurate size classification, high throughput, and reliable performance—especially in fine and ultra-fine size ranges.

Operating at 2,800 to 6,000 RPM, High Frequency Screens are engineered to handle the hard, abrasive nature of silica sand while delivering sharp separation and stable operation.

Why High Frequency Screens Are Ideal for Silica Sand

Silica sand is used in multiple industrial applications where particle size accuracy directly affects product performance. Conventional screens often struggle with blinding, low efficiency, and inconsistent cut sizes. High Frequency Screens overcome these challenges through high-speed vibration and rigid screen construction.

Accurate Fine Screening of Silica Sand

High Frequency Screens provide:

- Sharp cut sizes below 1 mm

- Narrow and repeatable particle size distribution (PSD)

- Clean separation of multiple silica sand grades

This makes them ideal for glass-grade silica sand, foundry sand, and industrial sand processing.

Stainless Steel Screening Media for Purity

High Frequency Screens used in silica sand plants typically employ stainless steel (SS) screening media, which offers:

- High resistance to abrasion

- Dimensional accuracy at high vibration speeds

- Suitability for high-purity silica sand applications

SS screening media ensures consistent aperture control, critical for premium silica sand markets.

Non-Blinding Performance with Fine Silica

Fine silica particles tend to clog conventional screens. High Frequency Screens operate with:

- High G-force vibration

- Low amplitude stroke

This prevents particle lodging, maintains open screening area, and ensures continuous, clog-free operation.

Reduced Over-Grinding and Energy Efficiency

Accurate classification ensures that only true oversize material is sent back for grinding, resulting in:

- Lower mill power consumption

- Reduced generation of excess fines

- Higher recovery of usable silica sand fractions

This improves overall plant energy efficiency and operating cost per ton.

High Throughput with Compact Footprint

High Frequency Screens allow:

- Thin material bed depth

- Faster material travel across the deck

This enables high capacity screening in a compact layout, ideal for space-constrained silica sand plants and retrofit installations.

Applications of Screened & Processed Silica Sand

Properly screened and processed silica sand is a critical raw material across multiple industries.

Glass Industry

- Float glass

- Container glass

- Specialty and solar glass

Requires narrow PSD and high purity silica sand.

Foundry Industry

- Moulding sand

- Core sand

Consistent grain size improves casting quality and surface finish.

Construction & Building Materials

- Plaster

- Flooring compounds

- Specialty mortars

Screened silica sand improves strength and workability.

Ceramics & Tiles

- Body and glaze formulations

Controlled particle size ensures uniform firing and strength.

Paints, Coatings & Chemicals

- Functional fillers

- Anti-abrasive additives

Fine silica sand enhances durability and chemical resistance.

Water Filtration

- Filter media for drinking and industrial water

Uniform grading ensures effective filtration performance.

Key Advantages of High Frequency Screens in Silica Sand Plants

- Operating speed: 2,800–6,000 RPM

- Precise fine screening of silica sand

- Stainless steel screening media for purity and durability

- Non-blinding performance with fine material

- Lower grinding energy and operating costs

- High throughput in a compact design

Reliable Screening Technology for Silica Sand Processing

High Frequency Screens are a proven solution for silica sand beneficiation plants, industrial sand processing units, and high-purity silica sand producers. They deliver consistent product quality, improved efficiency, and long-term reliability for demanding silica sand applications.

CRUXTOR High Frequency Screening Technology

CRUXTOR delivers high-frequency screening technology for modern manufactured sand plants, designed for precise particle size distribution control, energy efficiency, and environmentally compliant dry processing. Also used in fines screening for metallic, non-metallic minerals, chemicals in solid bulk material handling.

CUSTOM DESIGNED FOR FOOD AND AGRO PROCESSING. WIDELY USED IN FERTILISERS.

KEY TECHNICAL FEATURES

CUSTOMER BENEFITS

CRUXTOR - PURPOSE-BUILT ENGINEERING

High Frequency Screens are designed not as generic equipment, but engineered specifically for sand producers who demand performance, control, and sustainability.

IS 383 - ZONE II & PLASTER SAND PSD REFERENCE

CRUXTOR High Frequency Screens allow tuning of amplitude and frequency at each deck, enabling producers to achieve IS 383 Zone II compliance or plaster sand gradation without water.

IS 383 Zone II: Standard specification for fine aggregate (sand) for concrete

Plaster Sand: Specially graded sand for plastering applications with controlled particle size distribution

APPLICATIONS OF HIGH FREQUENCY SCREENS

Metallic Minerals

- Iron ore fines

- Copper ore

- Zinc & lead ores

- Manganese ore

- Chromite

- Bauxite

- Gold ore (pre-classification)

Non-Metallic Minerals

- Quartz & silica sand

- Feldspar

- Limestone & dolomite

- Kaolin & china clay

- Bariter

- Talc

- Phosphate rock

- Bentonite

- Garnet

- Fluorspar

Sand Processing & Manufactured Sand (M-Sand)

- Manufactured sand (M-Sand)

- Plaster sand (P-Sand)

- Crusher dust processing

Quartz, Silica & High-Purity Materials

- Quartz sand classification

- Quartz powder production

- High-purity silica sand

- Foundry silica sand

- Industrial silica sand

Fertilizer Industry Applications

- Urea

- DAP

- MAP

- NPK

- SSP

- Potash

Chemical Industry Applications

- Soda ash

- Calcium carbonate

- Sodium bicarbonate

- Industrial salts

- Sulphur granules

About CRUXTOR

High Frequency Screen.

At Cruxtor, we strive to revolutionize the material handling equipment industry by providing advanced screening solutions. Our focus is on delivering innovative technologies, such as fine screening technology and high frequency screens, that enhance operational efficiency and productivity. We also cater to specific needs, including M Sand Plants and sugar graders, ensuring our clients receive the best solutions for their requirements.

Our Vision

At Cruxtor, we strive to revolutionize the material handling equipment industry by providing advanced screening solutions. Our focus is on delivering innovative technologies, such as fine screening technology and high frequency screens, that enhance operational efficiency and productivity. We also cater to specific needs, including M Sand Plants and sugar graders, ensuring our clients receive the best solutions for their requirements.

Contact Us

Drop us a line!

MAIL US YOUR REQUIREMENT

For inquiries about our advanced screening solutions, including fine screening technology and high frequency screens for M Sand Plants and sugar graders, please reach out to info@cruxtor.com.

CRUXTOR

Pune – Gaurav Icon Tower, Sr. No. 153/17, Opposite Tip Top Hotel, Next to Lifepoint Hospital, Mumbai–Pune Expressway, Pune – 411057, Maharashtra, India

📞 +91 70125 18523

📧 info@cruxtor.com

Hours

| Day | Hours |

|---|---|

| Mon | 09:00 am – 05:00 pm |

| Tue | 09:00 am – 05:00 pm |

| Wed | 09:00 am – 05:00 pm |

| Thu | 09:00 am – 05:00 pm |

| Fri | 09:00 am – 05:00 pm |

| Sat | Closed |

| Sun | Closed |

Subscribe

Sign up to hear from us about our advanced screening solutions, including specials on fine screening technology, sales related to high frequency screens, and events featuring our M Sand Plant and sugar grader.